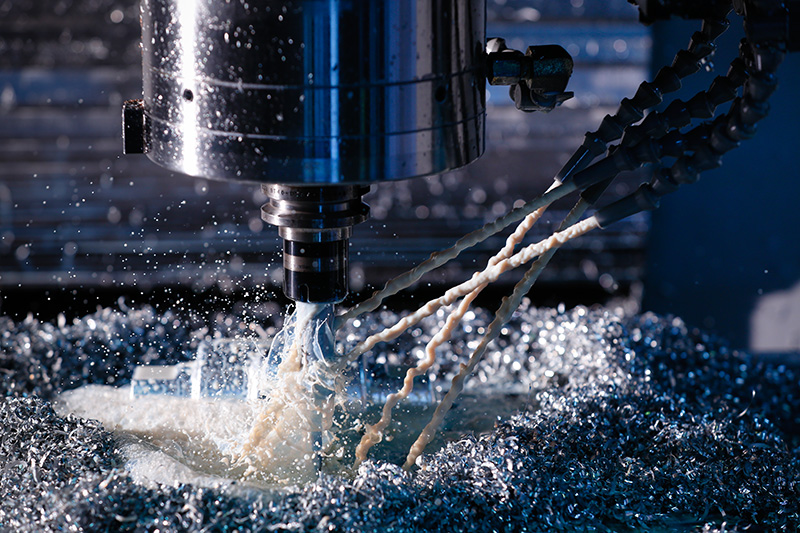

Universal CNC machines are used to process complex products made from various types of cast irons produced by our foundry, as well as from other materials, at the customer’s request. Processing is performed using different operations, such as turning, milling, drilling, slotting and balancing.

|

Machine |

Max. turning diameter [mm] |

Max. turning length [mm] |

||||

|

OKUMA&HOWA |

Ø 580 |

635 |

||||

|

2SP-V55 |

||||||

|

OKUMA&HOWA |

Ø 610 |

635 |

||||

|

2SP-V60 |

||||||

|

DAEWOO PUMA |

Ø 730 |

750 |

||||

|

V550-2SP |

||||||

|

DAEWOO PUMA |

Ø 730 |

750 |

||||

|

V550 (4 machines) |

||||||

|

DAEWOO PUMA |

Ø 496 |

488 |

||||

|

V400 (2 machines) |

||||||

|

Machine |

Max. turning diameter [mm] |

Max. turning length [mm] |

||||

|

DAEWOO PUMA 300 |

Ø 400 |

660 |

||||

|

(2 machines) |

||||||

|

DAEWOO PUMA 280 |

Ø 420 |

658 |

||||

|

|

||||||

|

DAEWOO PUMA 240 |

Ø 350 |

550 |

||||

|

(2 machines) |

||||||

|

DAEWOO PUMA |

Ø 356 |

1298 |

||||

|

CT-250 (driven tools) |

||||||

|

MORISEIKI NL 2500 |

Ø 356 |

705 |

||||

|

MC-700 |

||||||

|

DAEWOO PUMA (driven tools) |

Ø 356 |

1298 |

||||

|

240M |

||||||

|

Machine |

Road axis [mm] |

Notes |

||||

|

DAEWOO ACE V400 |

x=560; y=400; z=570 |

|

||||

|

(2 machines) |

||||||

|

DAEWOO ACE VC400 |

x=560; y=400; z=570 |

1 machine with Renishaw |

||||

|

(2 machines) |

measuring system |

|||||

|

DAEWOO ACE V430 |

x=560; y=430; z=570 |

1 machine with Renishaw |

||||

|

(3 machines) |

measuring system |

|||||

|

Machine |

Max. dimension |

Road axis [mm] |

Range size [mm] |

Max. Ø of tool |

Notes |

|||||||

|

MoriSeiki NH 5000/BT40 |

O 730 x 900 |

x=630; y=600; z=670 |

500 x 500 |

80 (180) |

|

|||||||

|

MoriSeiki NH 5000/BT40 |

O 610 x 900 |

x=630; y=600; z=670 |

500 x 500 |

80 (180) |

3 palettes |

|||||||

|

MoriSeiki NH 5000/BT50 |

O 730 x 900 |

x=650; y=600; z=810 |

500 x 500 |

120 (250) |

Renishaw measuring system |

|||||||

|

MoriSeiki SH 403 |

O 610 x 650 |

x=560; y=510; z=510 |

400 x 400 |

80 (125) |

||||||||

|

KITAMURA |

O 500 x 560 |

x=610; y=510; z=510 |

400 x 400 |

95 (150) |

B-axis=0,001o |

|||||||

|

MoriSeiki |

O 800 x 1000 |

x=730; y=730; z=850 |

500 x 500 |

110 (300) |

B-axis=0,001o |

|||||||

|

DAEWOO |

O 800 x 950 |

x=800; y=700; z=750 |

550 x 550 |

125 (250) |

|

|||||||

|

OKUMA MB-4000H |

O 600 x 900 |

x=560; y=560; z=625 |

400 x 400 |

70 (150) |

Renishaw measuring system B-os=0,001o |

|||||||

|

OKUMA MB-5000H |

O 800 x 1000 |

x=760; y=760; z=780 |

500 x 500 |

70 (150) |

Renishaw measuring system B-os=0,001o |

|||||||

Surface protection

Grey cast iron is a material that oxidizes very quickly when exposed to moisture. For this reason we also provide, in addition to processing, surface protection using the phosphatising procedure or oil paints, which serve as rust protection.

Tool-making Shop

For the needs of the workpiece production process, we very often have to make special-purpose clamping and control devices as well as special-purpose cutting tools. That is why we have our own tool-making shop at the Mechanical Processing Department. A tool-making shop means quicker response times and greater flexibility for both our production process and our customers.